Part of the site of the Ynysfach Ironworks (a separate, but integral part of the great Cyfarthfa Ironworks of the Crawshay family) in Merthyr Tydfil was excavated by the Glamorgan-Gwent Archaeological Trust in 2011 prior to the development of ‘The College Merthyr’ (a new tertiary education facility developed by Merthyr Tydfil County Borough & The University of South Wales).

The excavations provided a unique opportunity for examinations of the structures and residues associated with the refinery process. Refineries were developed in Merthyr Tydfil in the late 18th century as an intermediate process to allow the newly-developed Cort's puddling process to convert grey cast iron smelted from the local sedimentary ironstones into wrought iron. The process involved remelting the pig iron under a strong air blast and then casting it into thin white cast iron slabs by chilling in an iron trough constructed over a cistern of water and with water sprayed onto the molten iron.

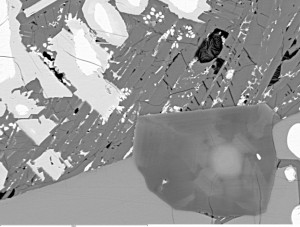

Slags produced during the process flowed off the surface of the iron and were collected for disposal. An accidental flow of slag into one of the drains allowed the confident attribution of the slag to the refinery process. The slags were characterised by a very high phosphorus content, leading to the development of phosphoran varieties of the common slag minerals as well as various phosphate phases. In particular phosphoran fayalite occurred widely, with compositions ranging up to the theoretical maximum degree phosphorus substitution.

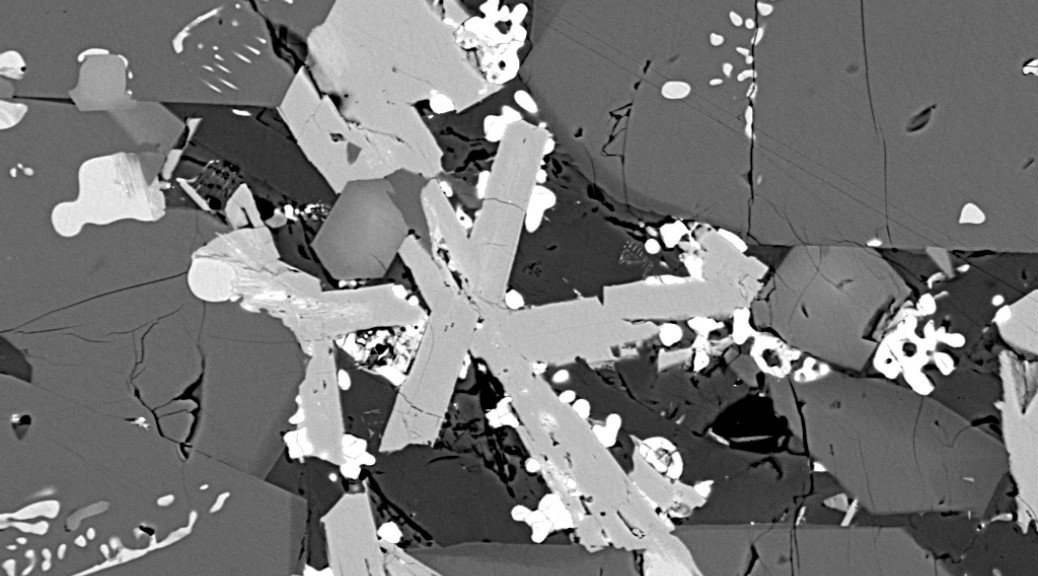

BSEM image of a refining slag. The phosphoran fayalite (lower) is the dominant phase. Ti, V, Cr -rich spinels (lower right) are also common. The interstitial area (upper) contains various phosphatic phases (dark) as well as wustite (bright) overgrown by phosphoran iscorite (pale grey).

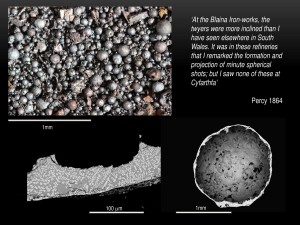

As well as the macroscopic slag flows, the refinery process produced microresidues of two types: small (<40μm) dense spheroids of iron or iron oxide and larger, 100-2500μm diameter, hollow spheroids of slag comprising magnetite dendrites in a glass or micro-crystalline matrix. The spheroids were probably generated by the turbulence of the air blast on the molten iron and slag in the refinery furnace respectively. The spheroids form a major component of the deposits in the site’s many drains.

These new data, together with reappraisal of contemporary accounts of poor quality puddled iron before the introduction of refining, suggest that control of phosphorus, in addition to the control of silicon, may have been a major factor in the need for the refining process.

(further details may be found on the Glamorgan-Gwent Archaeological Trust's website - http://www.ggat.org.uk/)