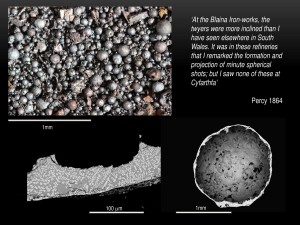

The proceedings of the Hüttenberg conference in 2008 are also now imminent. The volume, edited by Brigitte Cech and Thilo Rehren is available from the publishers (éditions monique mergoil) for 56.00€.

The volume runs to 300 pages plus 20 plates and contains 23 papers on bloomery iron-making and related issues from across the continent.